Except aesthetic and functional characteristics, the strength of furniture structure is another important indicator to measure the quality of furniture. For many years, design of furniture structure has been using empirical exploration, experimental methods and simplified theoretical calculations. Despite the analysis of furniture structure, designers have established many theories through long-term practice and have also obtained reliable data through a large number of experiments and have developed corresponding standards. But these experiences, experiments, and simplified calculations consume a lot of materials and resources. Accurate calculation of the furniture structure requires a more scientific and rational approach.

The finite element method is very effective for the analysis of furniture structure, also adapt to the requirements of the development of furniture design to high-tech. this method extremely improve the quality of furniture design, shorten the design cycle and reduce the cost. It has become a powerful tool to improve the creativity and scientificity of modern furniture design and enhance market competitiveness. However, the analysis process of large-scale general finite element software is complex, requiring users to have a certain finite element theory foundation, and it is difficult for furniture designers to learn the analysis method in a short time, which leads to the development of this method in the furniture design industry.

Simright has launched the online structure analysis software Simulator with navigation menus, highly automated pre-processing settings and a rich video tutorial that allows even finite element zero-based users to quickly comprehend analytical methods.

Before on sale, Furniture must go through the design, sample and test process to ensure that the product meets retail standards. A furniture manufacturer performed a structural analysis of the chair to be tested by the Simulator, ensuring that the chair can withstand the body weight, maintain its shape, and not flex under certain conditions before the sample is tested. During the life of the chair, it can withstand thousands of repeated loadings to ensure that cracking, cracking or bending will not occur, which is perfect for furniture designers.

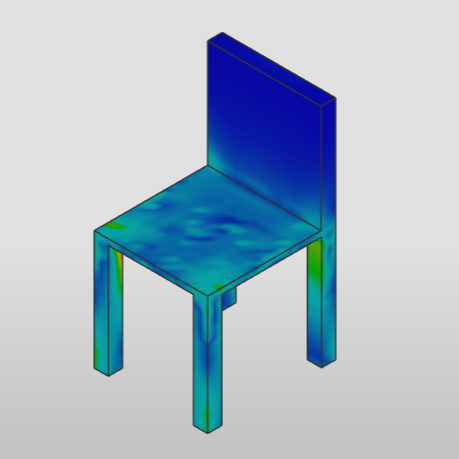

First introduce geometric model of the chair in Simulator, select the material of from material library and give it. The load on the chair is simulated by applying a uniform force on the seat surface, and the bottom surface of chair leg is restrained. After completing above simple setup, you can submit to calculation, which takes only 10 seconds. According to the calculation results, the maximum stress value of chair is 37.64Mpa, the maximum displacement value is 0.03mm, the stress distribution is relatively uniform, maximum stress value is much smaller than allowable stress of the material, and the overall structural deformation of chair is small.

Traditional destructive mechanical tests will consume a large amount of test materials, and the theoretical calculation analysis methods are cumbersome and inaccurate. Compare with this, the finite element software is used to analyze the furniture strength with parameters that are easy to adjust, quick to solve, accurate in calculation, and intuitive in effect. Many advantages are revealed. Through the final analysis results, the designer can intuitively understand the strength of each part of the furniture structure, thus providing a comprehensive reference standard for the next step of furniture optimization design, and greatly reducing the design cost.